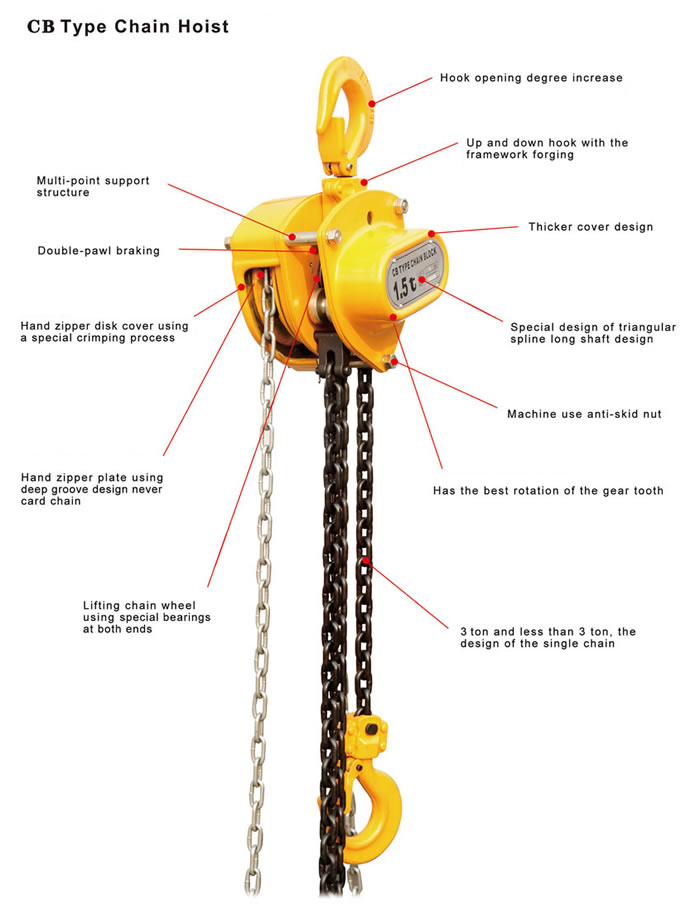

Manual Chain Hoist Structure

CB type hand chain hoist

When Manual chain hoists lifting weights upward, hands and pulled clockwise chains, bracelets wheel rotates counterclockwise when pulling hands to pull the chain down the stopper with separate brakes, ratchet pawl still under the effect of the five tooth long axis lifting sprocket drive runs in the opposite direction, so that the weight steady decline. Chain hoists generally use one-way ratchet friction disc brake, brake in the load on their own, with the ratchet pawl engages under the action of the spring, the brake safety. It is safe, reliable, easy maintenance, high mechanical efficiency, bracelets pull small, light weight and portability, smaller size and beautiful appearance, durable and suitable for factories, mines, construction sites, wharves, docks and warehouses for installation of equipment, lifting goods, especially for open and no power supply, but also shows its superiority. Selection of main parts chain hoists steel materials, the use of chain 800 Mpa high strength lifting chain, material is generally 20M2, intermediate frequency quenching, low wear, corrosion of the chain; high-strength hook material is generally steel, forging playing style hook design ensures slow lifting to prevent overload; meet European CE safety standards.

评论

发表评论